Robot Guidance Technology To Integrate Digital Twin Into Manufacturing Digital Thread

True Position Robotics (TPR) has entered into a two part digital project collaboration with Spirit AeroSystems, on project DELTA (Digitally Enabled Low-Cost Technologies for Aerostructures).

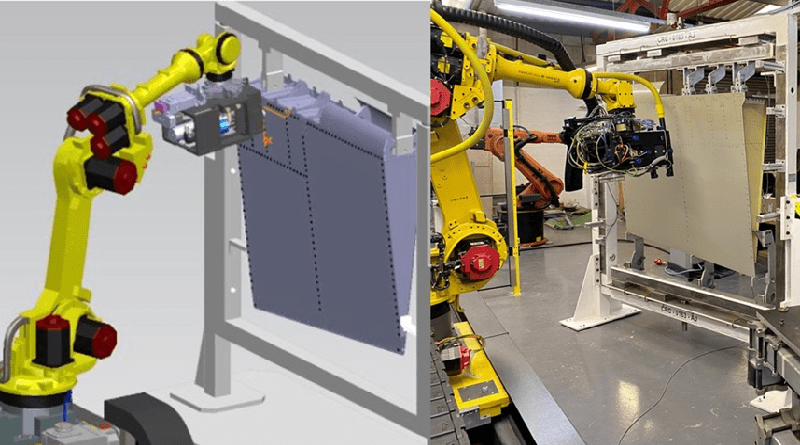

The first element is the integration of TPR’s robotic drilling system into the ‘digital thread’ which includes full off-line robot programming, using Siemens PLM, and TPR’s robot guidance technology to create an absolute digital twin.

The drill is a low payload, low energy, and a concession-free solution (part of Net Zero manufacturing strategy); ideal for affordable automation of aerostructure small assemblies (hole sizes up to 10mm). The size also enables access around products previously unobtainable on the market. This project focusses on ¼” countersunk holes.

This solution is proven to deliver ‘True Position’ significantly higher than aerostructure design book tolerances, with countersink CpK >4.

The second element of the project includes the integration of ‘Polyworks Data Loop‘; a web-based server, not only used for operations / conformance, but integrated into the digital thread to share learning across the enterprise. Working closely with 3D Scanners (Master Distributor for InnovMetric in the UK), TPR will integrate database with a number of different devices and demonstrate digital ‘fit’ back into the Siemens PLM.