Automated EV Battery Weld Seam Inspection Uses 3D Laser Line Scanning Sensors

An innovation leader in automotive lightweight construction, Waldaschaff Automotive is meeting the complex challenges in subassembly with cutting-edge solutions from SmartRay.

The manufacturing process for high-voltage battery housings, also known as battery frames or trays, is challenging due to the size of the housing, and the process steps required to combine the individual components into the finished product. The battery housing is a complex structure with seams that are difficult to reach and inspect. However, by utilising SmartRay’s industry-leading sensor system for weld seam inspection, Waldaschaff was able to inspect 100% of the weld seams on each component, improving quality, efficiency and accuracy.

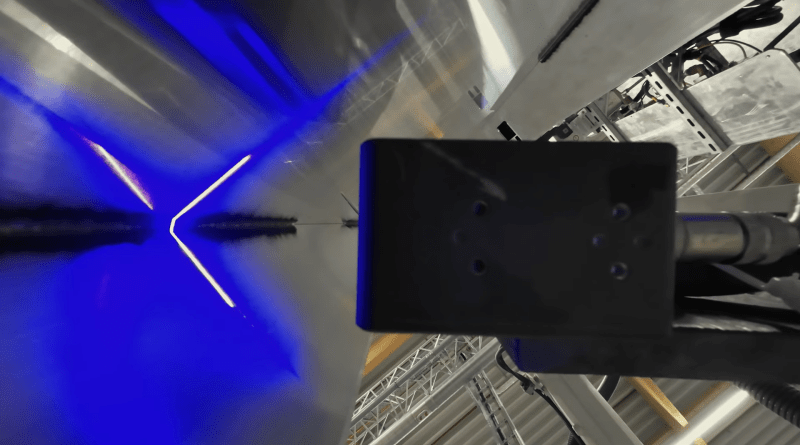

JOSY is a high-speed, all-in-one system for non-contact, 3D visual inspection of joining technologies and weld inspection. The system incorporates pre-calibrated 3D sensors with intelligent software tools and advanced algorithm processing to deliver high-accuracy weld inspection that meets international standards.

Waldaschaff has installed 16 JOSY weld inspection systems across four production lines, on different battery housings. In total, about 200 MIG and laser welds are checked, enabling Waldaschaff to manage the welding process proactively and preventively, saving time and material through a more efficient rework process.

“The SmartRay system enables us to inspect 100% of the weld seams on each component objectively, optically, and in a norm-based way, and this is essential to secure our quality” stated Klaus Steigerwald, Head of Customer Unit at Waldaschaff Automotive.