Taqtile Leverages Spatial Computing To Advance Antiquated Inspection Processes

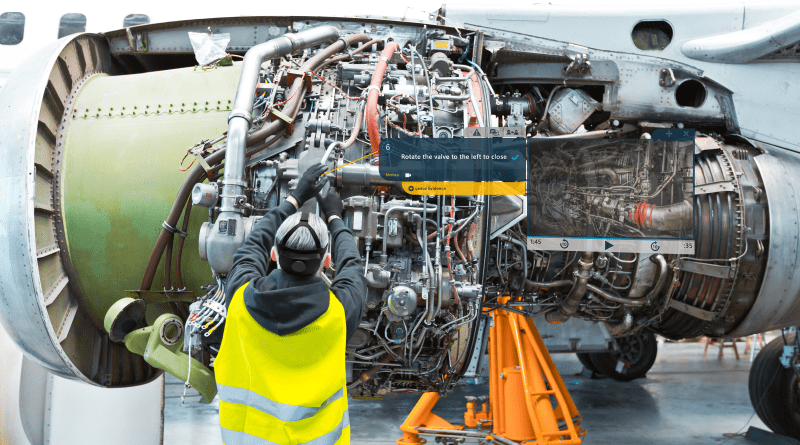

Taqtile, a leader in augmented reality (AR)-based work instruction solutions, has announced a dramatic advance in how industrial and defense industry customers conduct inspections and track equipment faults. With newly introduced innovations implemented in Manifest, users can more efficiently and thoroughly flag faults identified within the inspection process and, subsequently, track and independently manage those faults. These new capabilities, combined with the innate power of the Manifest spatial-computing system, enable organizations to conduct inspections more efficiently while simultaneously decreasing human error traditionally found in paper-based systems.

Inspections are critical to both industrial and defense operations. Historically, inspections are also time-consuming, inefficient undertakings that often suffer from incomplete and inaccurate reporting. Manifest elegantly addresses these issues, optimizing inspection workflow by providing step-by-step instructions for users to follow, and capturing critical data – which faults occurred, where they occurred, and when they occurred – throughout the fault management and resolution processes. Once a fault is flagged and fundamental information is captured, industrial and defense users can leverage Manifest to assign tasks to individuals or teams, and track resolution activity through completion.

Spatially place faults over equipment: Workers can utilize the Manifest AR environment or head-mounted displays (HMDs), tablets like the iPad, or other mobile devices to easily locate equipment with faults, and then access associated data via the Manifest platform.

Assign fault notes: Administrators can mandate the capture of specific fault information, i.e., photos and/or pen notes, creating a fault history that accurately and comprehensively documents issues so they can be resolved faster and more completely.

Tasks: Non-procedural work assignments can now be associated with a specific fault, delegated to team members, or cataloged as a stand-alone task and tracked independently of a pre-assigned job.

Audit trails and reports: Organizations can create audit trails and automatically generate inspection reports, eliminating extra paperwork and decreasing errors.

“Inspection and compliance processes are arduous, requiring excellent communication and precise documentation if organizations hope to efficiently and successfully resolve faults as they occur. Our customers need more usable, robust tools that empower them to achieve their goals,” said John Tomizuka, CTO, Taqtile. “Spatially enabling these processes will revolutionize how our industrial and defense customers conduct inspections, resolve faults, and support their deskless workers.

The new inspection capabilities are optimized for a variety of headset and device platforms, including the iPad, a popular inspection device for manufacturers due to its versatility and intuitive, familiar interface. Taqtile exists to empower and equip people with the tools they need to complete their jobs flawlessly, accurately, every time. By leveraging proven technologies, including spatial computing, augmented reality, 3D visualization, and real-time collaborative communication, Taqtile’s Manifest platform empowers deskless workers to complete complex tasks more efficiently, completely, and safely than ever before.