3D Scanner Launched For Large Part Measurement

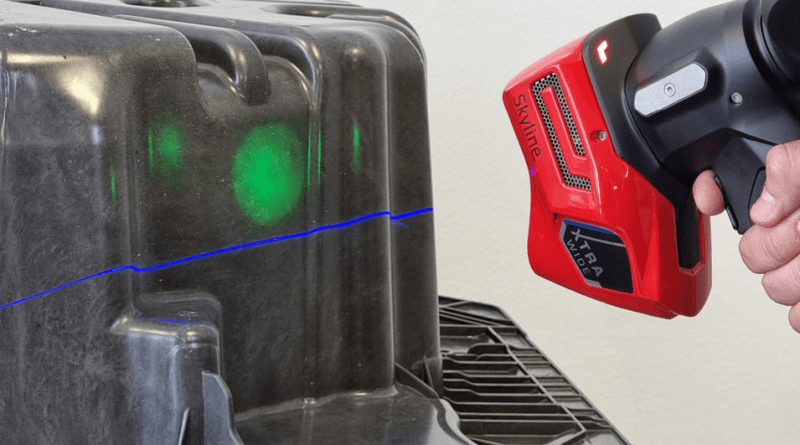

Kreon Technologies has announced that innovation in 3D scanning technology has reached new heights with the launch of its latest achievement: the Skyline XTRA WIDE. Building upon the success of its predecessors, the Skyline XTRA WIDE 3D scanner is a cutting-edge device that promises to augment the 3D scanning experience through its remarkable extra-wide laser line width for scanning large parts of any industry.

Unleashing Unparalleled Performance

At the core of Skyline XTRA WIDE lies a commitment to unparalleled performance. Boasting a 300 mm wide laser line designed to examine massive parts in any circumstance within seconds by reducing the number of scan passes throughout the manufactured piece.

The ultra-fast acquisition speed of 600.000 pts/sec allows the scanner to capture dense points cloud over the surface. The high frequency assures the speedy movement of the Kreon’s 3D scanner. Moreover, due to blue laser fineness, the scanner offers an optimal accuracy of 28 µm even on shiny reflective surfaces.

Skyline XTRA WIDE is a precise 3D measurement tool that ensures rapid scanning, enabling comprehensive coverage and capturing even the smallest details with clarity.

Integration With Kreon Measuring Arms

A standout feature of Kreon’s range of Skyline 3D scanners is its seamless integration with the Kreon measuring arms. The synergy between the hardware devices enhances the scanner’s ergonomic design and facilitates effortless scanning. The Skyline XTRA WIDE is no exception and offers users a streamlined and intuitive experience of accessibility and productivity.

This integration of an industrial 3D Scanner and measuring arm can be digitally portrayed to Zenith, a 3D scanning software. Zenith focuses on the essential functions used in most applications for acquisition and 3D measurement like probing measurement and color mapping.

Extended Versatility

Whether it is automotive or aerospace manufacturing, the Skyline XTRA WIDE is tailored for a wide range of applications from quality control with GD&T verification to reverse engineering. From small components to large-scale objects, the 3D scanner delivers consistent results across the board.