Manufacturer Leverages Integrated Machine Vision To Drive Growth

Since cameras were first introduced in industrial manufacturing lines in the 1980s, factory teams have relied on them for one task – to detect quality issues. While the cameras and technology evolved – the use case did not.

One New Brunswick, USA based company – Eigen Innovations – backed by global technology leader Intel, is changing that, helping manufacturers unlock the full potential of machine vision. Using it to not only detect quality issues, but to empower teams to determine the cause and solve problems faster.

“We’re advancing how industrial machine vision is used today, giving factory teams the tools they need to move from detection to prevention – empowering them to be the best they can be,” explains Eigen CEO Erin Barrett. “Changing the long-held perceptions and competing with established brands in the machine vision space is a significant challenge. This kind of support and exposure from Intel is massive for our company and, most importantly, it provides an incredible opportunity to shine the spotlight on our customers.”

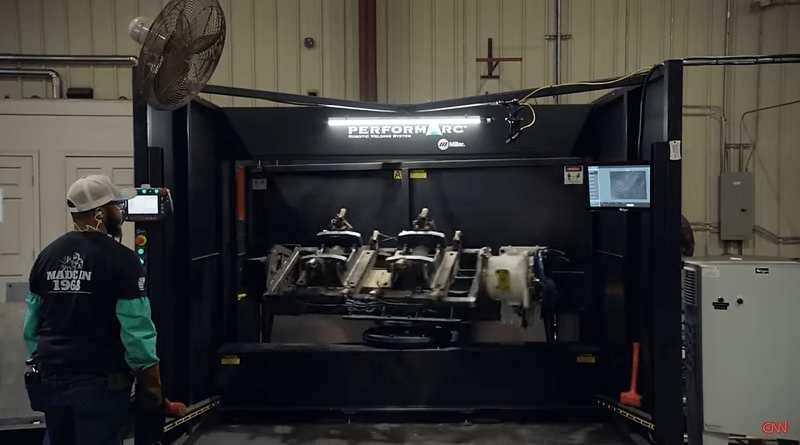

When Intel approached Eigen about participating in this marketing campaign, the team immediately thought of one of its customers – North Carolina-based metal fabricator, Southern Fabricators. The company’s owners/managers are adopting machine vision to empower their workforce and help them drive growth – including hiring more workers.

“Southern Fab was the ideal customer to profile in this campaign,” said Jonathan Weiss, Eigen’s Chief Revenue Officer. “The Carpenter family is keenly aware of the importance of investing in technology. They want their team to be able to focus on high-value work rather than redundant tasks like visually inspecting every part. And they wanted a flexible vision solution that can expand and evolve along with their business.”

A Decade of Factory Experience

Eigen has spent the last 10+ years in factories developing tools and solutions that help manufacturers do more with the images they capture in factories. The company developed novel ways to process images to make them more readily useable and meaningful. Its OneView software consolidates images from multiple cameras to create one complete, standardized image. Factory teams can use these images to create and manage in-line inspections – something that no other machine vision company provides.

Along with generating consistent, consolidated images, the software maps data from other sources onto the standardized inspection images. This allows teams to pinpoint the location of defects and to determine what happened during the manufacturing process to cause them. Along with comprehensive inspections, it provides factory teams with the consistent data that they need to introduce AI and automation.

“When it comes to Industry 4.0 and Digital Transformation, there has been plenty of talk and evidence of the benefits, but adoption has been slow,” says Jonathan Weiss, Eigen’s Chief Revenue Officer. “There is a long list of reasons for this but we found it often boils down to not having in-house resources to get the technology in place and lacking the standardized data required to enable the AI and automation. Our vision solutions and software tackle both of those challenges.”

Optimizing Solution Performance with Intel

Eigen bases its vision solutions on Intel-powered CPU processors due to their computing power and ability to perform harsh factory conditions. Intel works closely with companies like Eigen to support manufacturers adopt digital solutions. The Intel Partner Alliance supports independent software companies like Eigen that build, deliver and optimize solutions on Intel processors and technology.

The Intel campaign called “it starts now” and the video featuring Eigen and Southern Fab. Over the coming weeks, Intel will promote the content to maximize exposure for Eigen and the other companies that are part of the campaign. And as the name suggests, it’s coming at a time when industrial digital transformation is gaining momentum.

“I said adoption has been slow but in reality, the digital transformation train has left the station,” says Weiss. “The tech is scalable. It’s been factory-proven. With ongoing labour shortages and increasing demands for quality assurance and product traceability, solutions like ours are increasingly not “nice-to-haves”, they are “must-haves.”